In the world of business operations, managing inventory is paramount to maintaining efficient supply chains and maximizing profitability. One crucial aspect of inventory management lies in understanding the concept of partially complete units. These units, often referred to simply as “WIP” (work in progress), play a significant role in determining production efficiency, cost analysis, and overall inventory valuation.

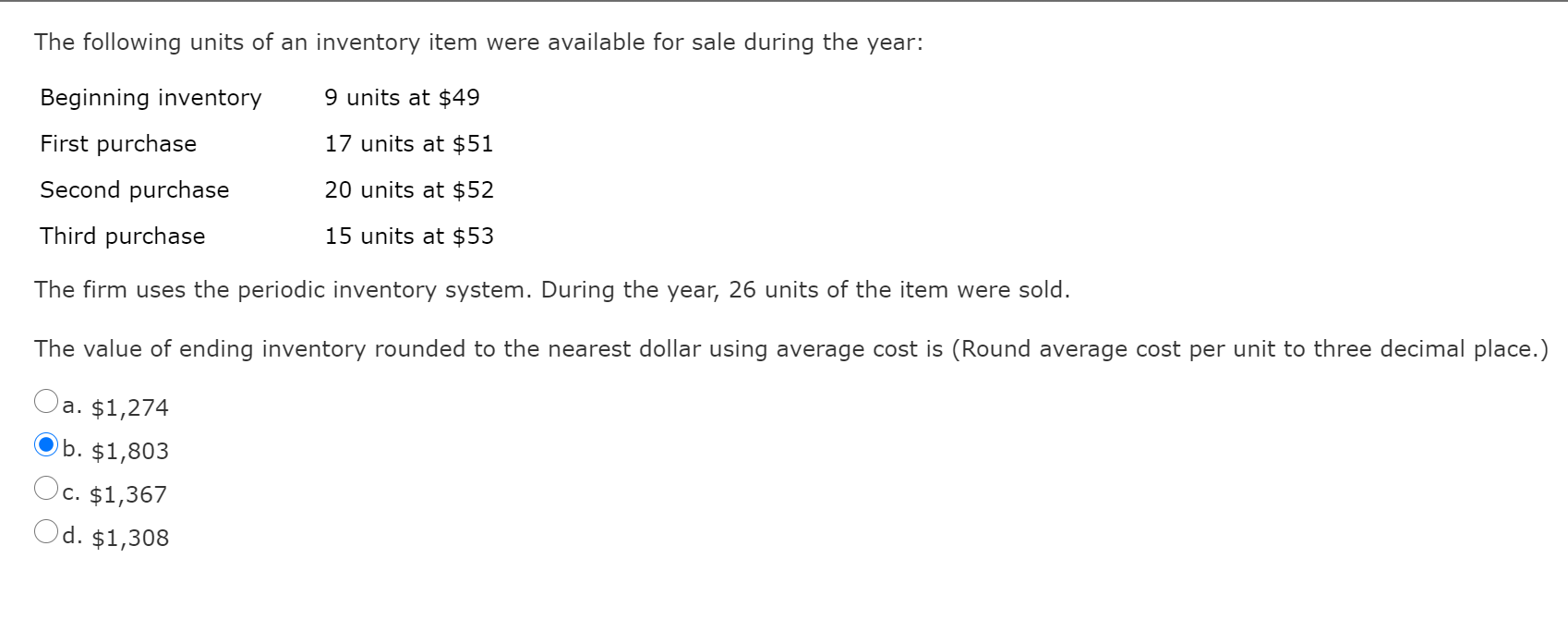

Image: www.chegg.com

Understanding Partially Complete Units

Partially complete units are inventory items that have undergone some level of production but have not yet reached their final form. They represent the stage at which production processes have begun but are not fully concluded. WIP accounts for units in various stages of completion, from raw materials that have undergone initial processing to components that are nearly ready for assembly.

Importance of Partially Complete Units

WIP holds substantial importance in inventory management for several reasons:

1. Production Efficiency: WIP provides insights into the efficiency of production processes. By monitoring the amount and duration of WIP, managers can identify bottlenecks, optimize production schedules, and reduce lead times.

2. Cost Analysis: WIP is crucial for accurate cost analysis. Including WIP in inventory valuation ensures that all production costs associated with incomplete units are accounted for. This allows for proper decision-making regarding pricing, production levels, and inventory turnover.

3. Inventory Valuation: WIP directly impacts the overall value of inventory. Companies must account for the costs incurred in the production of WIP to determine its fair market value. This process enables accurate financial reporting and helps prevent over or underestimation of inventory values.

Management of Partially Complete Units

Effective management of WIP is essential to optimize inventory efficiency and profitability. Several key strategies are commonly employed:

1. WIP Kanban Systems: Kanban systems use visual cues to regulate the flow of WIP through production processes. By limiting the amount of WIP in each production stage, Kanban systems help minimize inventory buildup and improve production efficiency.

2. Just-in-Time (JIT) Production: JIT is a manufacturing approach that aims to reduce WIP levels by producing goods only as they are needed. By eliminating excess WIP, JIT focuses on minimizing inventory carrying costs and reducing waste.

3. Lean Manufacturing Principles: Lean manufacturing principles emphasize the reduction of waste and the implementation of continuous improvement practices. By eliminating unnecessary WIP and streamlining production processes, lean manufacturing techniques enhance efficiency and improve overall performance.

4. Enterprise Resource Planning (ERP) Software: ERP systems provide real-time tracking of WIP throughout the supply chain. This centralized data repository helps managers monitor production flows, identify bottlenecks, and make informed decisions to optimize WIP management.

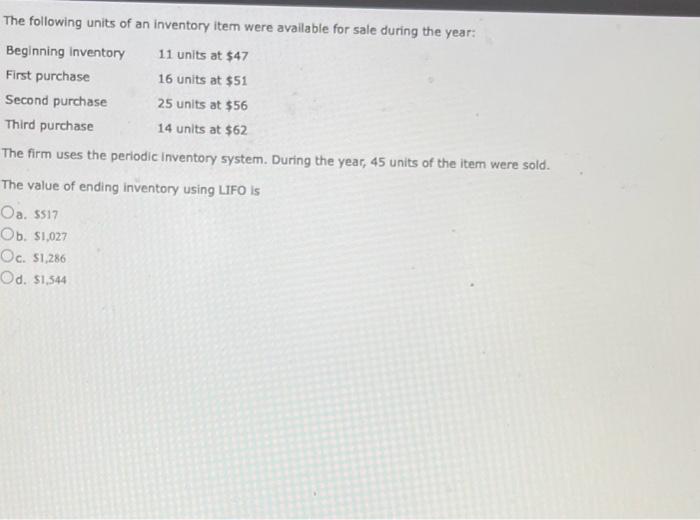

Image: www.chegg.com

Partially Complete Units Are Known As Inventory.

Conclusion

Partially complete units are an essential aspect of inventory management, providing valuable insights into production efficiency, cost analysis, and overall inventory valuation. By implementing sound WIP management strategies, companies can optimize production processes, minimize inventory carrying costs, and enhance profitability. Understanding and effectively managing WIP is therefore paramount for any business seeking to maintain efficiency and competitiveness within the complex and demanding world of inventory management.